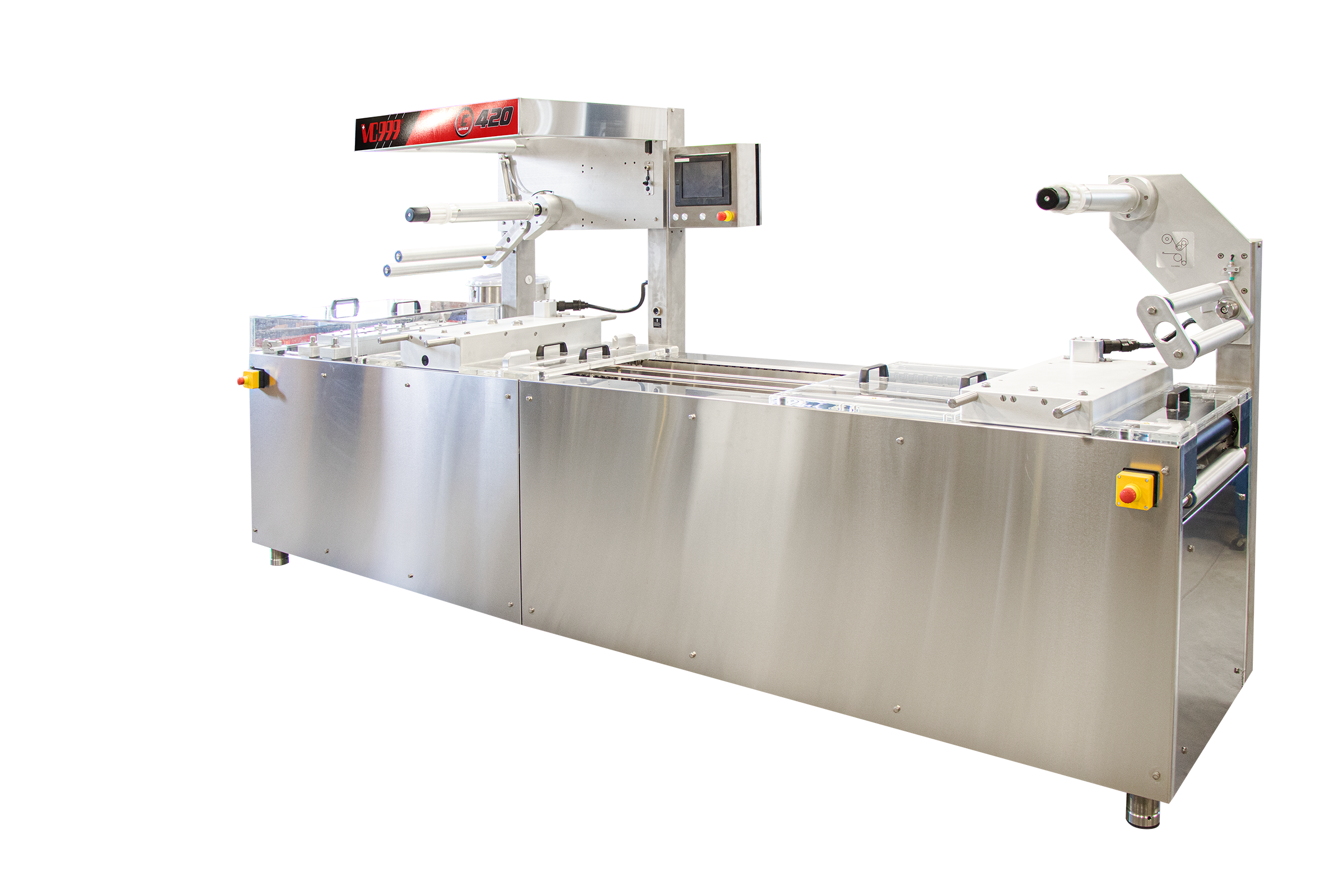

2. When the long-term cost savings is important:

Although the initial investment in a thermoforming machine may be higher than a tray sealer, the long-term cost savings can be significant. With less labor required, less materials bought, and overall lower operating costs over time.

3. When you have a wide range of packaging styles:

Thermoformers offer greater versatility in packaging options compared to tray sealers. Instead of being limited to a specific tray size and shape, thermoformers can adapt to a wide range of packaging sizes, shapes, and materials.