The I-Series combines industry-leading technology to achieve superior safety and sanitation levels. The support team is responsive and globally accessible. Built to exceed the highest global safety, hygiene and sanitation standards. Designed on a multi-lingual platform.

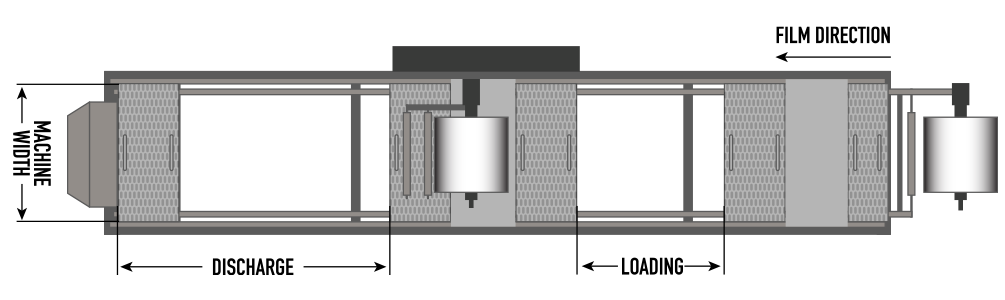

Standard Machine Widths

285 / 320 / 355 / 420 / 459 /520 / 560 / 620 / 720 mm

Max. Index Length

up to 1200 mm

Standard Loading Lengths

1300 – 4800 mm (300mm increments)

Standard Discharge Lengths

900 – 3900 mm (300mm increments)

Draw Depths

100 / 135 / 185 mm

Film Roll Diameter

up to 400 mm (standard) / 1500 mm (jumbo)

Roll Core

76 mm / 3” (standard) 152 mm / 6” available

Power Supply

220/440V – 3 ph – 50/60hz

Compressed Air

min. 7 bar (103 psi) @ 850 l/min.

MADE IN THE USA

Automatic Chain Lubrication

Coding & Printing Devices

Confirmation Station

Conveyors

Customized Form & Sealing Tooling

Gas Testing Devices

Heavy Product Support

Hole Punch Devices

Jumbo Power Unwind 1500 mm

Labeling Devices

MAP Gas Options

Multiple Cutting Options

Plug Assist

Printed Film Registration

(Slot Sensor or Color Photo Eye)

Product Support Wire

Remote EWON Access

Shrink Application

Sandwich Preheat

Seal Only

Skin Pack

(Below Web Line)

Tear Notch

Water Chiller